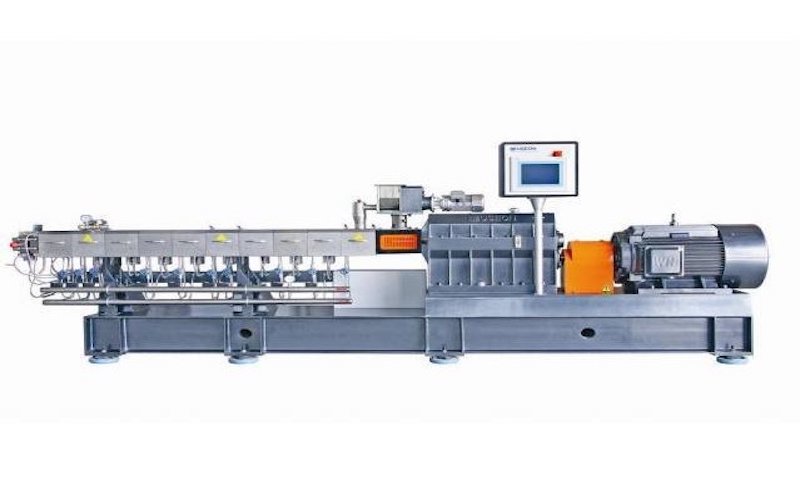

TWIN SCREW EXTRUDER

About Flavia Twin Screw Compounding System

Parallel Co-rotating twin-screw extruder is widely used in filling, blending, modification and reinforcement of rubber and plastic and engineering resin, and devolatilization treatment of chlorinated polypropylene and super absorbent resin; Extrusion of degradable masterbatch, polyamide polycondensation and polyurethane addition polymerization; Granulation of carbon powder and magnetic powder, preparation of insulating material, sheath material, low smoke and low halogen flame retardant PVC cable material and various silane crosslinking materials for cables, etc.

Product Range of Flavia Twin Screw Extruder

| Model | Screw Diameter | Screw Length | Motor Power | Max.Screw Speed | Reference Output |

|---|---|---|---|---|---|

| FSHJ-20 | 21.7 mm | 28~52 L/D | 4~5.5kW | 600~800 rpm | 5~20 kg/h |

| FSHJ-35 | 35.6 mm | 28~52 L/D | 22~45kW | 600~800 rpm | 50~150 kg/h |

| FSHJ-50 | 50.5 mm | 28~52 L/D | 75~110kW | 600~800 rpm | 150~400 kg/h |

| FSHJ-65 | 62.4 mm | 28~52 L/D | 110~200kW | 600~800 rpm | 400~800 kg/h |

| FSHJ-75 | 71 mm | 28~52 L/D | 160~355kW | 600~800 rpm | 500~1000 kg/h |

| FSHJ-95 | 92 mm | 28~52 L/D | 280~650kW | 600~800 rpm | 1200~2000kg/h |

| FSHJ-135 | 132 mm | 13~36 L/D | 280~450kW | 200~300 rpm | 1500~3000 kg/h |

Features of Flavia Extruder

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua ut enim ad minim veniam.

Contact Us Now

For detailed information, please drop us a line. We will contact you within 12 hours.